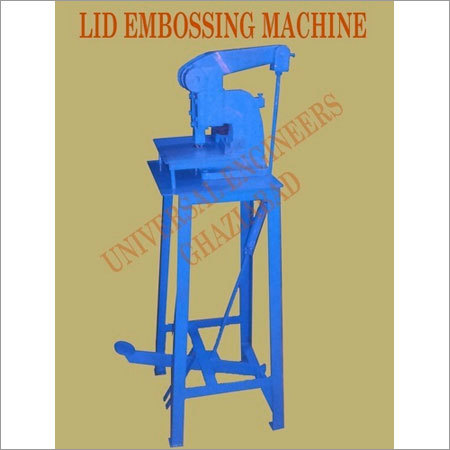

TIN LID Embossing Machines

Price 40000.0 INR/ Unit

TIN LID Embossing Machines Specification

- Lubricating System

- Automatic Lubrication

- Frame Type

- Welded Heavy Steel Frame

- Model No

- TLE-4000

- Voltage

- 380 V / 415 V Volt (v)

- Cooling System

- Air Cooling

- Operating Temperature

- 5C - 45C Celsius (oC)

- Connectivity Options

- Standard Electrical Fittings

- Accuracy

- High-precision mold alignment %

- Plastic Processed

- N/A for Metal Tin Lids

- Features

- Heavy Duty Construction, Consistent Embossing, Adjustable Pressure

- Noise Level

- < 75 dB db

- Drive

- Hydraulic Drive

- Machine Type

- Can/Tin Lid Embossing

- Power Rating

- 5.5 kW

- Frequency

- 50 Hz Hertz (HZ)

- Motor Power

- 5 HP Horsepower (HP)

- Production Capacity

- 3500-4000 lids/hour Liter/day

- Product Type

- Embossing Machine

- Technology

- Hydraulic Press Technology

- Power Source

- Electric

- Power

- 5.5 kW Watt (w)

- Pressure

- Hydraulic, adjustable up to 25 Tons PSI

- Surface Treatment

- Powder Coated / Painted

- Dimension (L*W*H)

- Approx. 2200 x 950 x 1800 mm Millimeter (mm)

- Weight (kg)

- 1800 kg Kilograms (kg)

- Color

- Industrial Blue & Yellow

- Usage & Applications

- Tin Lid Embossing, Can & Container Lid Surface Branding

- Energy Efficiency

- Optimized hydraulic system with low power consumption

- Cycle Time

- 3-5 seconds per lid

- Max. Lid Diameter

- Up to 153 mm

- Mold Change Time

- 15-20 minutes

- Machine Finish

- Rust Resistant

- Embossing Depth

- 0.3 mm to 0.8 mm adjustable

- Safety Features

- Emergency Stop, Overload Protection, Safety Guard

- Utilities Required

- Three-phase electricity

- Embossing Thickness Range

- 0.18 mm to 0.32 mm

- Die Material

- High-grade Tool Steel

- Operator Required

- 1-skilled operator

TIN LID Embossing Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 25 Units Per Month

- Delivery Time

- 3 Week

About TIN LID Embossing Machines

High-Speed Performance & Versatility

With rapid cycle times and a capacity topping 4000 lids per hour, the TIN LID Embossing Machine maximizes productivity in tin lid branding and container closure applications. Its versatile mold system accommodates varying embossing depths and tins up to 153 mm in diameter, making it adaptable for a wide range of embossed lid designs. The machines robust build ensures continuous and reliable operation.

Advanced Safety and Efficiency Features

Safety is prioritized with integrated emergency stops, overload protection, and a durable safety guard, ensuring secure operation for a single skilled operator. Its hydraulic system is optimized for energy efficiency, while a PLC control panel streamlines adjustments. The automatic lubrication and air cooling systems minimize maintenance downtime and prolong operational life.

Precision Engineering & Durable Construction

Engineered with a welded heavy steel frame and high-grade tool steel dies, the TLE-4000 maintains precise alignment during each embossing cycle. A powder-coated, rust-resistant finish promises lasting durability, even under intense, frequent use. Adjustable pressure up to 25 tons allows for consistent quality across various lid specifications.

FAQs of TIN LID Embossing Machines:

Q: How does the TIN LID Embossing Machine ensure accuracy in embossing?

A: The machine features high-precision mold alignment and uses high-grade tool steel dies to deliver consistent and accurate embossing on each lid. The PLC-controlled panel further allows operators to fine-tune parameters for optimal results.Q: What is the process for changing molds, and how long does it take?

A: Changing molds on the TLE-4000 is a straightforward process that typically takes between 15 to 20 minutes, thanks to its user-friendly design and accessible components. This allows for quick transitions between different lid designs or sizes.Q: When should the machine be operated, and at what conditions?

A: The machine is designed to run efficiently in industrial settings, ideally within an ambient temperature range of 5C to 45C. It operates on a three-phase electrical supply (380V/415V, 50Hz) and is suitable for round-the-clock use with minimal downtime due to its durability and automated features.Q: Where can this embossing machine be used?

A: The TIN LID Embossing Machine is ideal for factories and manufacturing units involved in tin can and container productions, particularly where high output, consistent branding, and durability are essential for can/tin lid embossing applications.Q: What are the benefits of using this particular embossing machine for tin lids?

A: Key benefits include rapid production cycles (3-5 seconds per lid), high-quality and consistent embossing, robust safety features, low power consumption, and minimal operator requirements. Its energy-efficient hydraulic system and heavy-duty frame ensure cost-effective, long-term operation.Q: How many operators are needed and what training is required?

A: Only one skilled operator is required to manage and operate the machine. Training involves familiarization with the PLC control system, safety features, and routine maintenance tasks, ensuring safe and efficient operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Canning Equipment Category

Lid Embossing Machines

Price 40000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Surface Treatment : Other, Powder Coated

Color : Blue & White

Usage & Applications : Metal & Plastic Lid Embossing for Packaging Industry

Exhaust Boxes (Can Sterlizer)

Price 130000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Surface Treatment : Other, Powder Coated

Color : Metallic Grey

Usage & Applications : Sterilization & Exhausting of Food Cans in Canning Lines

Industrial Canning Retorts

Price 80000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Other, Electric

Surface Treatment : Other, Polished Stainless Steel

Color : Metallic Silver

Usage & Applications : Food canning, beverage canning, seafood canning, readytoeat packaging

Can Seamer Machines

Price 110000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Surface Treatment : Other, Powder Coated

Color : Blue & Grey

Usage & Applications : Seaming and sealing of food, beverage, chemical, and paint cans

|

UNIVERSAL ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry