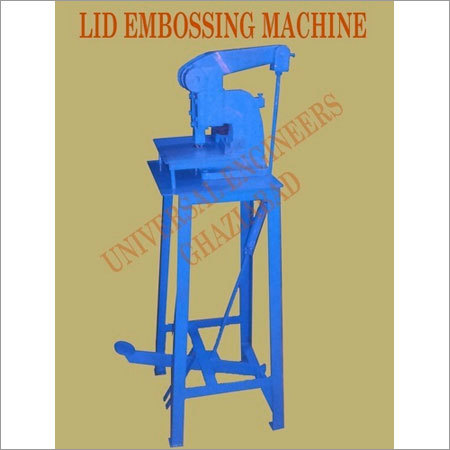

Lid Embossing Machines

Price 40000.0 INR/ Piece

Lid Embossing Machines Specification

- Connectivity Options

- Standard Electrical Interface

- Control System

- PLC Controlled

- Model No

- LEM1000

- Machine Type

- Embossing Press

- Noise Level

- < 70 dB db

- Voltage

- 380 V Volt (v)

- WorkingSpeed

- 50 Cycles/Minute

- Frame Type

- Heavy-Duty Steel Frame

- Lubricating System

- Automatic

- Drive

- Servo Motor Driven

- Production Capacity

- 5000-6000 Pieces/Hour Pcs/hr

- Power Rating

- 3.5 HP

- Frequency

- 50 Hz Hertz (HZ)

- Operating Temperature

- 5C - 45C Celsius (oC)

- Motor Power

- 3 kW Kilowatt (kW)

- Features

- High Precision, Low Maintenance, Quick Die Change

- Plastic Processed

- PP, PET, Metal Lids

- Accuracy

- 0.1 mm mm

- Cooling System

- Air Cooled

- Product Type

- Lid Embossing Machine

- Technology

- Mechanical Embossing

- Power Source

- Electric

- Operating Type

- Automatic

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 1600 mm x 900 mm x 2000 mm Millimeter (mm)

- Weight (kg)

- 1300 kg Kilograms (kg)

- Color

- Blue & White

- Usage & Applications

- Metal & Plastic Lid Embossing for Packaging Industry

- Environmental Compliance

- RoHS & CE Approved

- Cycle Time

- 2.5 Seconds/Cycle

- Die Change Time

- <15 Minutes

- Safety Features

- Emergency Stop, Overload Protection

- Embossing Plate Material

- Hardened Steel

- Suitable Lid Diameter

- 55-120 mm

- Embossing Depth

- 0.2-1.2 mm

- Available Accessories

- Spare Dies, Tool kit, Lubrication Kit

- Installation Type

- Floor Mounted

- Maintenance Requirement

- Low

- Operator Requirement

- Single Operator

Lid Embossing Machines Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 3 Week

- Main Export Market(s)

- Australia, North America, South America, Asia, Central America, Western Europe, Eastern Europe, Middle East, Africa

- Main Domestic Market

- All India

About Lid Embossing Machines

Exceptional Precision and Performance

The LEM1000 offers accurate and consistent embossing results with a 0.1 mm precision. Driven by a servo motor and controlled via PLC, the machine ensures each cycle is completed swiftly in only 2.5 seconds. Designed to handle large production volumes, it can process between 50006000 lids per hour, making it suitable for medium to large-scale packaging operations.

Easy Operation and Rapid Die Change

Only one operator is needed to run the LEM1000 efficiently. Its ergonomic design and automated features, including fast die changes in less than 15 minutes and an automatic lubricating system, reduce both labor and downtime. Accessories like spare dies, a toolkit, and a lubrication kit add further convenience for maintenance and operation.

Comprehensive Safety and Compliance

Safety is ensured with built-in emergency stop and overload protection. The system adheres to RoHS and CE standards, demonstrating environmental responsibility. Its powder-coated, heavy-duty steel frame enhances durability and safety. Floor-mounted installation provides stability, while noise levels are kept below 70 dB for a safer workplace environment.

FAQs of Lid Embossing Machines:

Q: How does the LEM1000 Lid Embossing Machine enhance production efficiency?

A: The LEM1000 delivers rapid embossing with a cycle time of 2.5 seconds, processing 50006000 lids per hour. Its automatic operation, quick die change in less than 15 minutes, and easy-to-use controls maximize output while minimizing downtime.Q: What types of lid materials can the machine emboss?

A: This machine is suited for both metal and plastic lids, including PP, PET, and various metal alloys. It supports lid diameters between 55 mm and 120 mm, offering flexibility for different packaging needs.Q: When is a die change required, and how is it performed?

A: A die change is typically needed when switching lid designs or sizes. The LEM1000 is engineered for quick die changes, taking less than 15 minutes with the included tools and spare dies, ensuring minimal disruption to production.Q: Where is the ideal installation location for the LEM1000?

A: The LEM1000 is designed for floor-mounted installation on a stable surface within industrial settings such as factories or packaging plants. Its robust frame ensures vibration-free operation and long-term durability.Q: What safety features are incorporated in the machines design?

A: Key safety features include an emergency stop button, overload protection, and compliance with RoHS and CE standards, all ensuring operator safety and machine reliability during operation.Q: How is the machine maintained and what are its maintenance requirements?

A: The LEM1000 requires minimal maintenance, thanks to features like an automatic lubricating system and a heavy-duty powder-coated frame. Regular checks and basic servicing using the supplied toolkit and lubrication kit will keep the machine running optimally.Q: What are the benefits of using this lid embossing machine in the packaging industry?

A: Benefits include high precision embossing, fast production speeds, reduced labor requirements, low maintenance, and environmental compliance, making it a reliable and cost-effective choice for packaging companies looking to enhance product presentation and throughput.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Canning Equipment Category

TIN LID Embossing Machines

Price 40000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Other, Electric

Usage & Applications : Tin Lid Embossing, Can & Container Lid Surface Branding

Color : Industrial Blue & Yellow

Surface Treatment : Other, Powder Coated / Painted

Exhaust Boxes (Can Sterlizer)

Price 130000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Usage & Applications : Sterilization & Exhausting of Food Cans in Canning Lines

Color : Metallic Grey

Surface Treatment : Other, Powder Coated

Industrial Canning Retorts

Price 80000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Other, Electric

Usage & Applications : Food canning, beverage canning, seafood canning, readytoeat packaging

Color : Metallic Silver

Surface Treatment : Other, Polished Stainless Steel

Can Hand Flangers

Price 75000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electricity

Usage & Applications : Industrial

Color : Blue

Surface Treatment : Painted

|

UNIVERSAL ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry